Electrical Grounding and Bonding: The Key to Electrical Safety

Have you ever thought about the electricity that powers your Santa Clara County home? It’s a powerful force that makes our lives more comfortable and convenient, but it can also be dangerous if not handled properly. Electrical accidents can lead to severe consequences, like electrocution, fires, and other damage. That’s why electrical safety should always be a top priority for homeowners. One of the most critical aspects of electrical safety involves electrical grounding and bonding.

Read on to learn more about these crucial safety systems and their differences.

What is Electrical Grounding?

Electrical grounding is connecting an electrical circuit to the earth to provide a safe path for electrical currents. It involves attaching a wire from the circuit to a grounding electrode, usually a metal rod or plate buried in the ground. The grounding electrode serves as a reference point for the electrical system. Any current that leaks from the system will flow through the electrode and into the earth.

Why is Electrical Grounding Important?

The primary purpose of grounding involves protecting people from electric shock, preventing dangerous electrical charges from building up in equipment, and safeguarding the electrical system from lightning strikes.

How Electrical Grounding Works

Electrical grounding provides a path of least resistance for electrical currents to flow. When an electrical fault occurs, such as a short circuit or lightning strike, current flows through the grounding system instead of through people or equipment. The grounding system offers low resistance to electrical currents, so the current flows to the earth without causing damage.

Types of Electrical Grounding

These are the three primary types of electrical grounding:

System Grounding: This type of grounding involves connecting one conductor of an electrical system to the ground. System grounding protects the electrical system from excess voltage caused by lightning, electrical surges, or other sources.

Equipment Grounding: This grounding type involves connecting non-current-carrying metal parts of equipment to earth ground. Equipment grounding protects people from electric shock.

Ground Fault Protection: This type of grounding involves using sensors to detect ground faults and disconnect power if necessary. Ground fault protection is essential for keeping people and equipment safe from electric shock caused by ground faults.

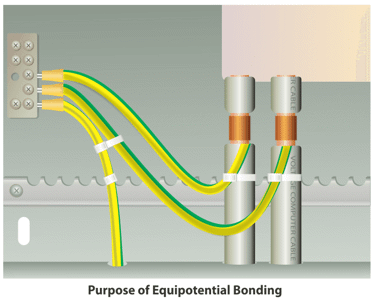

What is Electrical Bonding?

Electrical bonding is the process of connecting two or more conductive objects to create a low-resistance path for current flow. Bonding aims to ensure that all conductive objects in an electrical system are at the same potential, reducing the risk of electric shock.

Why is Electrical Bonding Important?

Electrical bonding helps prevent electrical shock by reducing the voltage difference between conductive objects in an electrical system. Bonding also certifies that all metal objects in an electrical system are at the same potential.

How Electrical Bonding Works

Electrical bonding works by connecting conductive objects to make certain they are all at the same potential. Electric potential is the amount of energy required to move electric charge from one point to another.

Think of electric potential in terms of a ramp. If the ramp is steep (two objects have vastly different electric potentials), electric charge can quickly move down the ramp like a slide, causing electrical arcs and sparks that can lead to damage or injury. When objects have the same potential, the ramp is flat, and the electric charge does not move between the two objects.

Types of Electrical Bonding

Several types of electrical bonding are used:

Equipment Bonding: This type of bonding involves connecting all non-current-carrying metal parts of equipment. Equipment bonding ensures that all metal objects in an electrical system have the same potential, reducing the risk of electrical arcing and sparking.

Enclosure Bonding: This type of bonding involves connecting all metal enclosures. Enclosure bonding guarantees that all metal objects in an electrical system are at the same potential, reducing the risk of electrical arcing and sparking.

Conductor Bonding: This type of bonding involves connecting all conductors. Conductor bonding checks that all conductors in an electrical system have the same potential, minimizing the risk of electrical arcing and sparking.

Differences Between Electrical Grounding and Bonding

While electrical grounding and bonding are similar in many ways, some critical differences exist between them. The main difference is that grounding involves connecting an electrical circuit to the ground, while bonding consists of connecting two or more conductive objects. Grounding is primarily concerned with the safety of people and equipment, while bonding is concerned with reducing the risk of electrical arcing and sparking.

5 Best Practices for Electrical Grounding and Bonding

To confirm that your electrical system is safe and reliable, following best practices for grounding and bonding is essential.

Understand the local electrical codes and regulations: Electric codes and regulations vary by location, so it is essential to understand the requirements in your area.

Conduct regular inspections: Regular inspections of your grounding and bonding systems can help detect and correct any issues before they become a problem.

Use high-quality materials: High-quality materials, such as copper or aluminum conductors and stainless steel electrodes, can ensure that your grounding and bonding system is reliable and long-lasting.

Correctly install the grounding and bonding system: Improper installation can reduce the effectiveness of the grounding and bonding system, so it is essential to follow the manufacturer’s instructions and local codes and regulations.

Test the grounding and bonding system regularly: Regular testing can help verify that your grounding and bonding system is working properly and providing the necessary protection.

Proper electrical grounding and bonding are essential for ensuring the safety of people and equipment in any electrical system. By following best practices and understanding the basics of grounding and bonding, you can confirm that your electrical system is safe, reliable, and efficient. If you’re working on a residential or commercial electrical system, always prioritize grounding and bonding.

Your Electrical Experts

Whether you’re dealing with installing a new electrical system or maintaining an existing one in Gilroy, CA, and the Santa Clara Valley, let Watson’s Charging Stations & Electric be your trusted guide. Our fully licensed team of electricians understands the importance of proper grounding and bonding in your home or business. More importantly, we can handle any electrical project that comes your way.

Contact us today to schedule your free consultation.